Glass breaking in the tempering furnace, commonly known as "furnace explosion", is an abnormal condition in the production of tempered Glass production.

Due to glass breaking in the tempering furnace, it is usually necessary to cool down and clean the furnace, which means a high loss of electricity for deep processing enterprises.

At the same time, due to the fact that it usually takes at least 24 hours for the tempering furnace to cool down, clean and wash the furnace, and then heat up again to resume production, the "explosion" of glass tempering can also have a certain impact on the production plan and order delivery of the enterprise.

So, tempering "blast furnace" is a production situation that all glass processing enterprises want to avoid.

So what factors are related to the "furnace explosion" during glass tempering? What are the corresponding measures?

Original film quality

Glass undergoes a process of rapid cooling and heating during the tempering process. During the process, the glass is subjected to thermal stress, and due to its brittleness, impurities contained in the original sheet or some small cracks on the surface can rapidly expand under the action of thermal stress, leading to glass fracture. Just like when a piece of paper is tightened, as long as there is a small crack, the paper will immediately break open from the crack.

The main factors that have a significant impact on the tempering furnace are stones, bubbles, and microcracks. The "blast furnace" during the tempering process of glass over 12mm is often caused by defects in the original sheet.

Therefore, avoiding "blast furnace" can purchase high-quality raw materials.

Cold working quality

Cold working leading to tempering "blast furnace" refers to the occurrence of cracks at the edges of glass during processes such as grinding, drilling, and slotting.

During the heating process of glass, the edges are subjected to the greatest thermal stress and are also the most prone to cracking. Therefore, tempered glass must be ground to eliminate cracks caused by the cutting edge.

The situation of drilling and slotting is the same as that of edge grinding, and cracks at the hole or slot positions should also be eliminated, otherwise the glass may also break from the cracks during the heating process.

So it is necessary to improve the quality of the pre tempering process and strengthen the inspection before entering the furnace. If cracks are found in the glass, the tempering process cannot be carried out.

Tempering process

The tempering process is also one of the main reasons for "furnace explosion". There are two main cases of improper processing, namely rapid heating and uneven heating.

Heating too fast is mainly related to excessively high temperature settings and excessive convection settings. Heating too fast refers to the rapid heating rate of glass after entering the furnace, which leads to high thermal stress of the glass and causes it to burst. Generally speaking, the thicker the glass and the larger the layout, the slower the heating speed should be. The "blast furnace" fragments caused by excessive heating are generally in the form of small fragments.

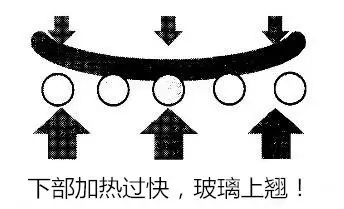

The uneven heating mainly means that when the glass is heated in the tempering furnace, the upper and lower sides of the glass are heated fast and the temperature is high, while the one side is heated slowly and the temperature is low. In this case, the glass will warp in the tempering furnace, with light cases showing white marks on the roller track, and heavy cases directly causing excessive deformation and breakage of the glass.

The situation of uneven heating is most common in the tempering of LOW-E glass, mainly relying on temperature and convection regulation. Directly observing the state of the glass in the furnace is an effective way to avoid it.

The entire Gangxin tempering furnace is controlled by an industrial control machine and PLC. The control system can automatically store and update the processing parameters of the glass, and the heating method adopts a spiral matrix structure to control the furnace temperature in different regions; The temperature control algorithm adopts module regulation, with strong anti-interference ability, high temperature control accuracy, and more stable and reliable performance; During automatic heating, three-phase balanced electricity consumption and automatic elimination of phase imbalance during non heating processes; In addition, the temperature fine-tuning control of the furnace can be achieved by adjusting the fine-tuning temperature of each heating electric furnace wire in the upper and lower parts of the furnace. Each furnace wire can be individually set for temperature and power, facilitating the operation of various types of glass.

Device abnormality

The "furnace explosion" caused by equipment abnormalities is mainly caused by the transmission system of the tempering furnace, commonly including roller bed jamming, length measurement abnormalities, and abnormal transmission encoder and frequency converter. In addition, regional temperature imbalance caused by local heating wire breakage or convection fan failure can also easily lead to "furnace explosion".

The Gangxin tempering furnace has a perfect monitoring function. The monitoring program can automatically monitor the working conditions of almost all Almost all and actuating elements, which can avoid the "furnace explosion" caused by equipment abnormalities.